DUNLEE CoolGlide™ LIQUID METAL BEARING

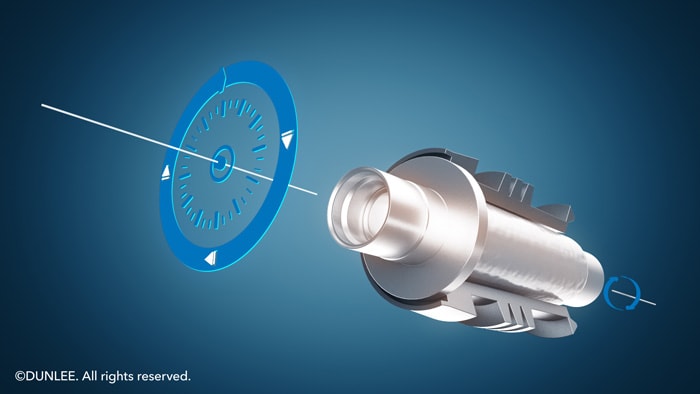

Dunlee’s CoolGlide™ Liquid Metal Bearings are designed and manufactured in Hamburg, Germany, based on knowledge gained from over 30 years of LMB technology development and over 100,000 LMB units sold worldwide.

The invention of Liquid Metal Bearing Technology by the Hamburg R&D team in 1989 had an enormous impact on performance and ease-of-use, becoming the gold standard for CT and Image Guided Therapy systems.

Continued refinements led to the introduction of CoolGlide™, the LMB technology now employed in Dunlee tubes. In comparison to traditional ball bearing tubes, CoolGlide™ LMB tubes are designed for higher throughput, faster workflow, lower noise, higher reliability and lower total cost. Let's compare:

CAN INCREASE PRODUCTIVITY: SCAN MORE PERSONS & DECREASE WAITING TIME

THROUGHPUT

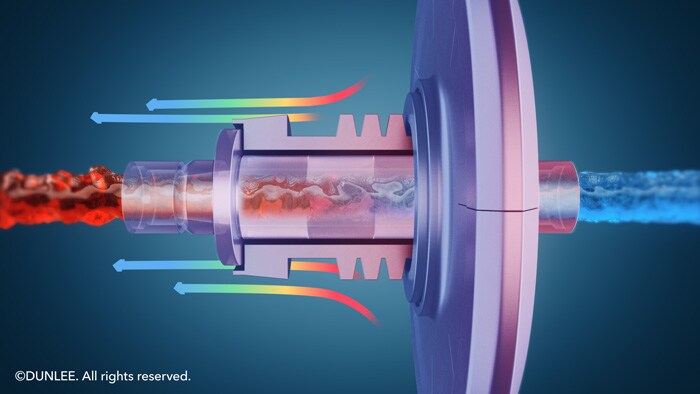

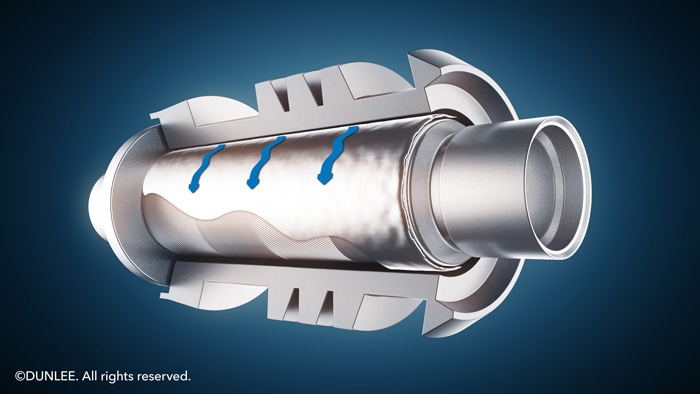

CoolGlide™ LMB – High Throughput / Excellent cooling capacity A cooling channel within the bearing shaft* directs cooling fluid to the anode. This design provides much higher heat conduction and cooling capacity than traditional ball bearing tubes. * Related to the Coolglide LMB design used in Dunlee‘s Xpert bundles. Dunlee offers different LMB designs, all designs provide high throughput / excellent cooling capacity.

Traditional Ball Bearing – Lower cooling capacity Lower heat conduction from the anode through the bearing as there is no direct cooling through the shaft. In contrast to CoolGlide™ LMB the ball bearing is an insulating barrier against heat conduction. This can result in overheating which requires pauses to wait for the tube to cool between studies, slowing down throughput.

WORKFLOW

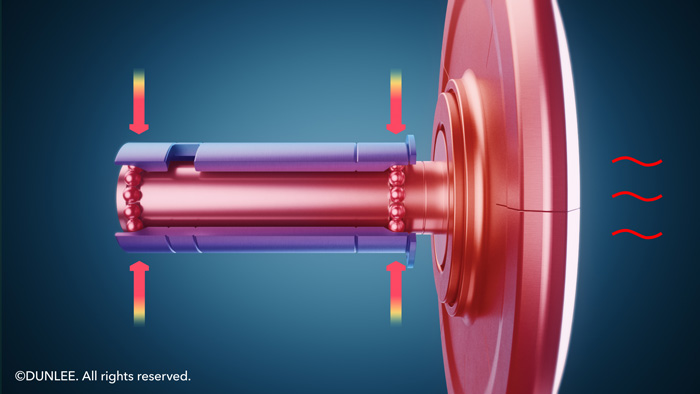

CoolGlide™ LMB – Faster Workflow / Continuous Anode Rotation The anode rotates continuously and provides constant high speed through the entire working day without stopping, speeding up workflow and facilitating productivity. There is no preparation time necessary between every scan, as there is for ball bearing tubes.

Traditional Ball Bearing – Anode rotation stopped after every scan Anode rotation for ball bearing tubes is started prior to a scan and stopped when the scan is finished. This approach requires preparation time for the tube for every scan.

RELIABILITY

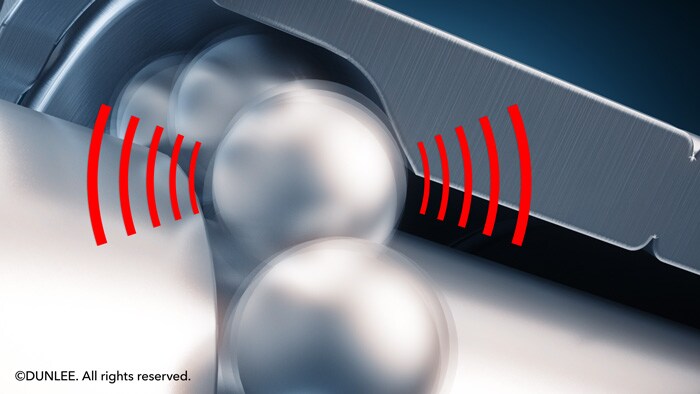

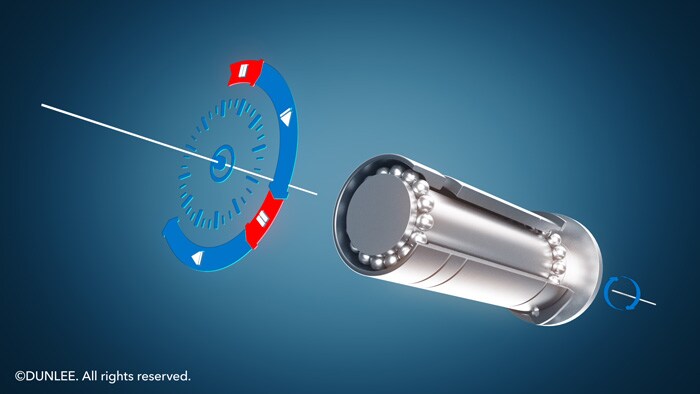

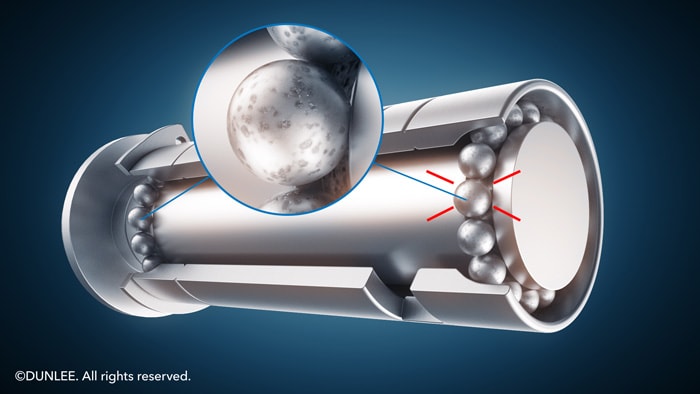

CoolGlide™ LMB – High Reliability / virtually no wear The bearing shaft and sleeve glide on a liquid film. The liquid is pumped to the interior of the bearing by spiral grooves. As there is no direct contact during operation, there‘s virtually no wear.

Traditional Ball Bearing – Wear off, risk of binding and jamming With operation, the lubricant (which is usually silver or lead metal) wears off of the ball and race surfaces, resulting in steel-to-steel contact that leads to binding or jamming. High temperature and high speed will reduce bearing life the most.

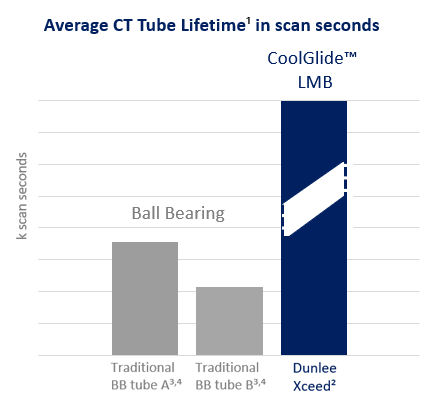

LIFETIME: BALL BEARING TUBES VS. LMB TUBES

REDUCING SYSTEM COSTS SIGNIFICANTLY

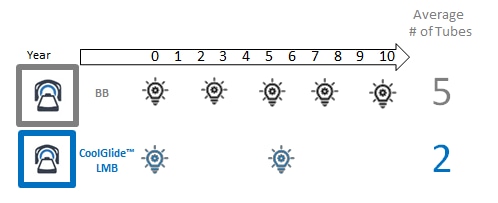

Total CT Tube consumption over lifetime Example of typical lifetimes of Ball Bearing tubes³ and CoolGlide™ LMB tubes²

CT utilization: 150.000 scan seconds p.a.

Due to frequent replacement, ball bearing tubes can create not only higher tube material costs, but also

- costs for field service personel

- inventory, freight and handling costs

DOWNLOADS

Sources & Remarks

About Dunlee