DECREASE TUBE ARCING TO ENHANCE CT WORKFLOWS

Efficiency is the engine that drives radiology departments. Disruptions in workflow and equipment downtime can disrupt scheduling, which may cause unacceptable patient waiting times, the need to reschedule appointments, and delayed diagnosis. To keep the department running smoothly, hospitals rely on medical systems that deliver high uptime, outstanding image quality and a flawless workflow with no interruptions. For CT systems, one common impediment to continuous operation and high image quality is tube arcing.

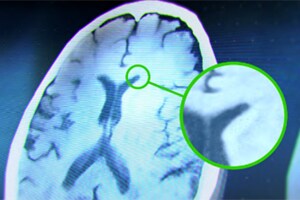

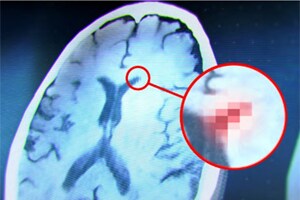

Tube arcing occurs when there is a short-circuit within the tube. This can result in a temporary loss of X-ray output. While arcing occurs in all medical X-ray equipment, CT is most affected by arcing artifacts, because a CT study comprises more projections than traditional radiography: While tube arcing may cause several negative issues, the most critical is the creation of imaging artefacts, which are when something is seen on an image that is not present in reality. Imaging artefacts make diagnosis more difficult.

Additional consequences of tube arcing are:

BENEFITS OF TUBES WITH LOW ARCING RATES

| | Benefits of X-ray tubes with low arcing rates | Disadvantages of X-ray tubes with high arcing rates |

| Higher staff and patient satisfaction Less arcing reduces the risk of scan termination and improves workflow due to fewer interruptions. |  Less interruptions, better workflow, which may lead to higher staff satisfaction |  Higher Risk of interruptions/ slower workflow |

| Better patient experience Less arcing decreases the risk of unnecessary repeat exposures, which decreases patient radiation dose. |  Better patient experience / less radiation dose |  Risk of higher radiation dose due to repeat exposures |

| Better health outcomes Less arcing lowers the risk of missed projections and image artefacts. |  Better health outcomes / lower risk of artefacts |  Higher risk of artefacts |

| Lower costs of care Less arcing reduces the risk of damage to the X-ray tube and/or generator. |  Lower costs of care / Lower risk of damage |  Higher risk of damages * / higher risk of downtime & maintenance costs |

* to the components or CT system

PREVENTING ARCING

To prevent arcing, hospitals need reliable CT systems manufactured with quality components. Dunlee’s tubes, generators and manufacturing processes are all designed to reduce arcing incidents.

Wear out of Ball Bearing tubes at end of bearing lifetime leads to higher friction inside the bearing, which leads to reduced anode frequency. Lower anode frequency is increasing the probability of arcing. Dunlee’s CoolGlide liquid metal bearings have virtually no wear-out and therefore these tubes have a lower arcing rate.

DUNLEE´S CT XPERT BUNDLE: FEEDBACK FROM THE FIELD

Dunlee’s X-ray products are famous for their low arcing rates. An extensive field monitoring study*** to assess the performance of our CT Xpert bundles in daily operation found high customer satisfaction with the bundle. Solution reliability proved to be outstanding, particularly the very low tube arcing rate, which the field study determined to be fewer than 1 scan interrupting arc* in 3 years.** This is achieved by the perfect alignment and integration of tube and generator in Dunlee’s Xpert bundle. It enables the tube to ride through up to 90 percent of tube arcs without interrupting the scan. * Scan interrupting arc is an arc that terminates a scan and makes a re-scan necessary.

** At an average utilization of 200 kss per year

*** available at Dunlee

VIDEOS

Learn more about Arcing in Dunlee’s webinar on you tube:

About Dunlee