TUNGSTEN PARTS MANUFACTURED IN THE EU

Our factory is located on the Philips Healthcare campus in the Dutch municipality of Best, from where our 3D printed parts are shipped to all major medical markets (EU, USA, Asia and many more).

THE FACTORY

Over the past few years, Dunlee has invested heavily in new 3D metal printers and post-processing capabilities. We are the only supplier that can print extreme accurate tungsten in high volumes while still meeting high quality standards.

PROCESSING TUNGSTEN

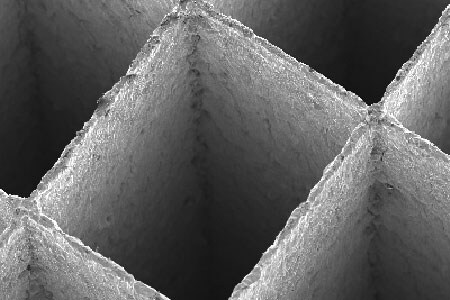

DMLS (direct metal laser sintering) is currently the most advanced 3D metal printing process, and offers the best price/performance ratios. By selectively solidifying thin layers of metal powder via laser beams, complex geometries can be realized layer by layer. Dunlee carefully monitors new 3D metal printing solutions and is committed to further developing its products and services.

UNIQUE POST-PROCESSING CAPABILITIES

To optimize the 3D-printed part, Dunlee has additionally implemented unique post-processing capabilities.

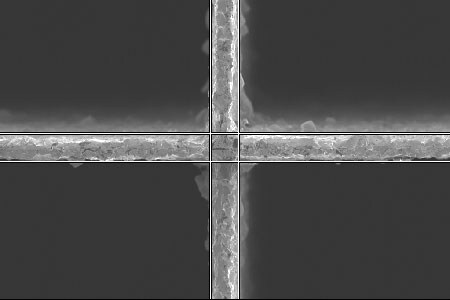

Surface treatment: optimizing mechanical accuracy Excellent mechanical performance

Coating: increasing mechanical performance High part durability and robustness

CONTACT

If you want to learn more about our in-house capabilities and expertise, don’t hesitate to contact us.

About Dunlee